Synopsis

Implementing Control Tower Management to ensure precise and timely delivery to assembly lines.

Customer Overview

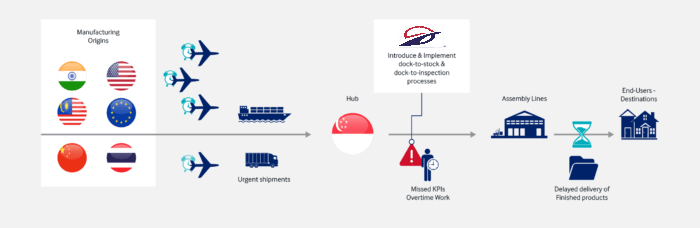

- A global US-based manufacturer assembles Electro-mechanic products in Singapore for Asia distribution.

- Origins: India, China, Thailand, Malaysia, US, EU

- Destinations: Singapore, Southeast Asia

- Industry: Industrial [niche market]

- Annual Business Volume: 3600 AWB / 5000 cbm

Challenges

- No visibility or pre-alerts on inbound cargoes to feed assembly lines

- Delayed customs clearance

- Increased urgent shipments

- Lack of supplier performance monitoring

- Missed KPIs

- Strained relationship with end-users

M&H Haulage Group Solutions

- Control Tower Management

- Process Re-engineering & Improvement

- Dock-to-Stock & Dock-to-Inspection

Benefits

- Enhanced Visibility and 2PL KPI’s through M&H Haulage Group’ implementing and managing the dock-to-stock / inspection processes

- Cost Savings: Saved over $100K after 6 months of implementation by eliminating urgent airfreight shipments and overtime work

- Timely Delivery to Assembly lines: Reduced import-for-delivery-to-assembly time from 72 hrs to 24 hrs. 200% improvement